Surface Shaping

Revolutionize Your Hydraulic Sealing Surfaces with SHS

Surface shaping in hydraulic systems has taken a giant leap forward with meso structures. These surface structures, with depths measured in micrometers and lengths in millimeters, offer an ingenious solution. They enable hydrodynamic pressure build-up while preserving the integrity of hydrostatic seals.

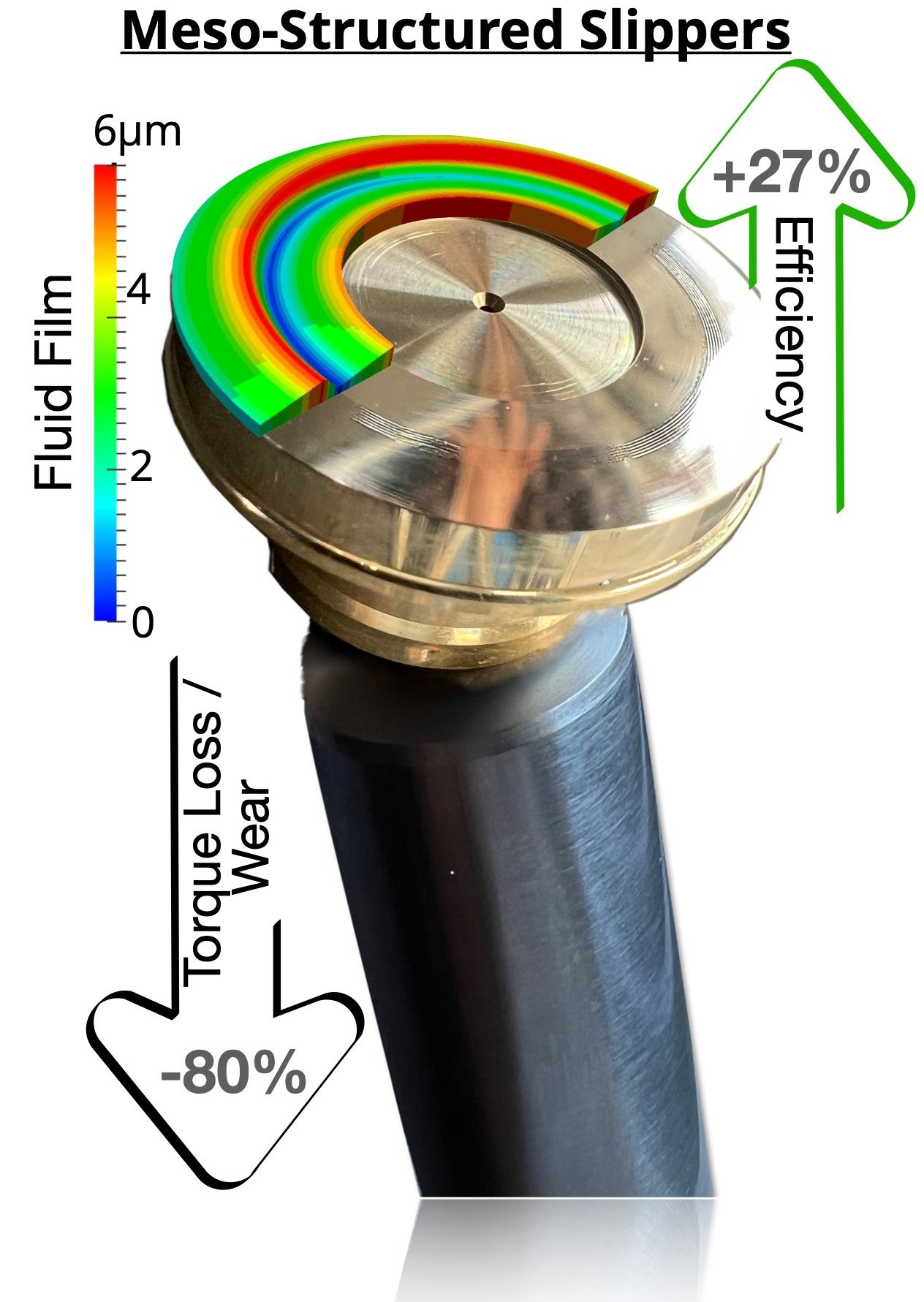

Through rigorous investigations with Caspar FSTI, we've uncovered the transformative potential of meso structures across all three sealing interfaces: cylinder block/valve plate, piston/bushing, and slipper/swash plate.

Published test rig results are nothing short of remarkable:

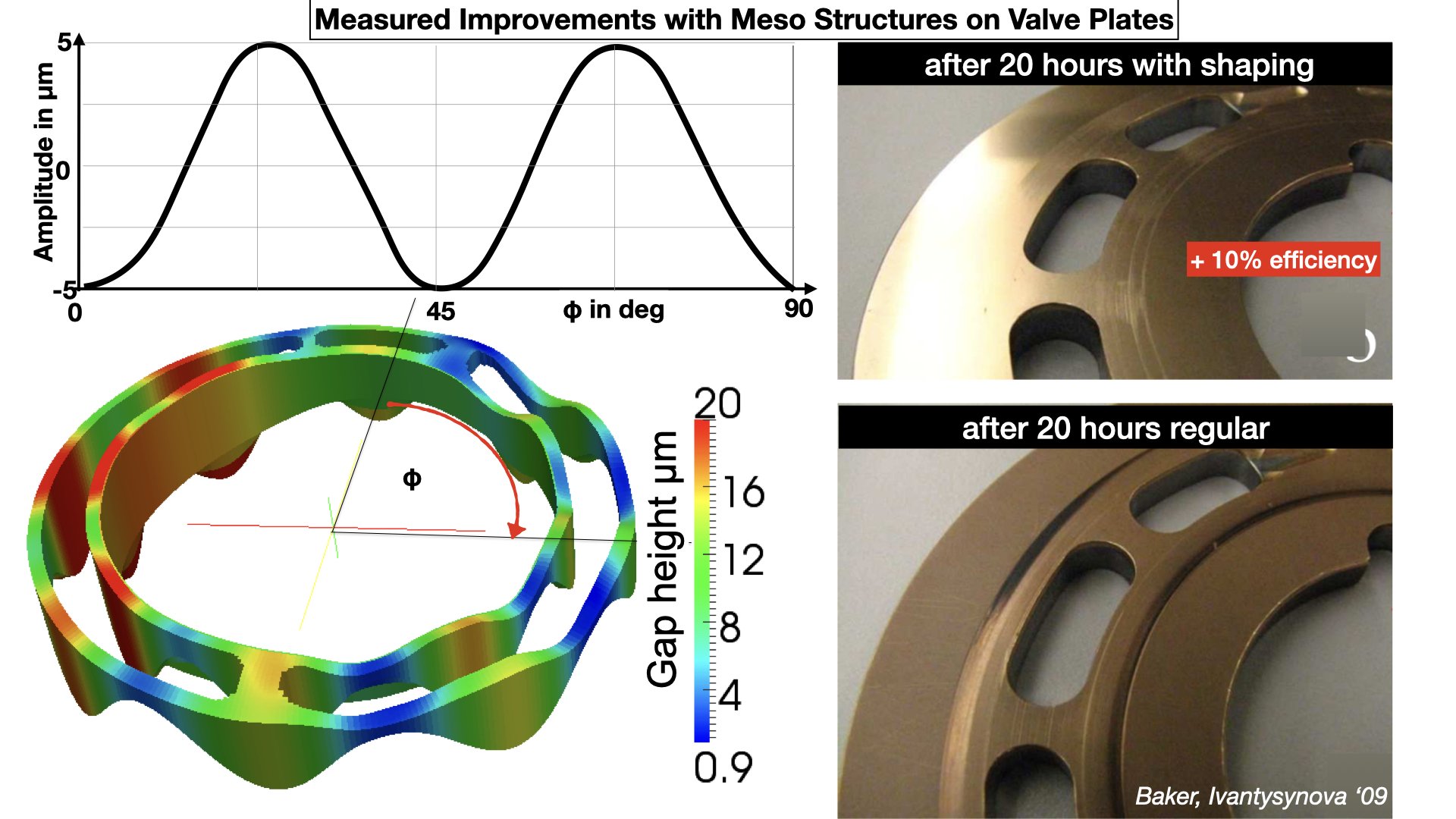

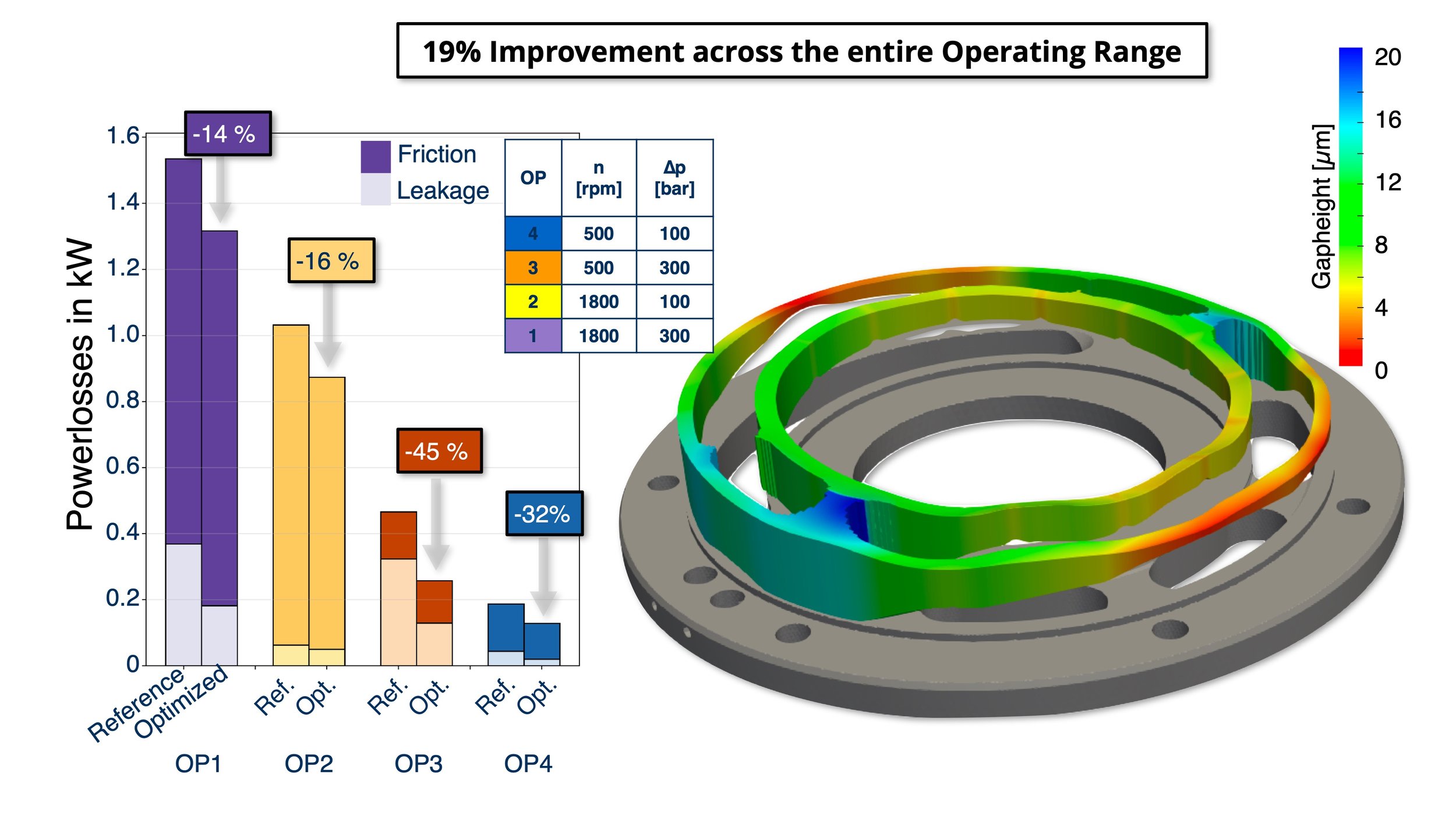

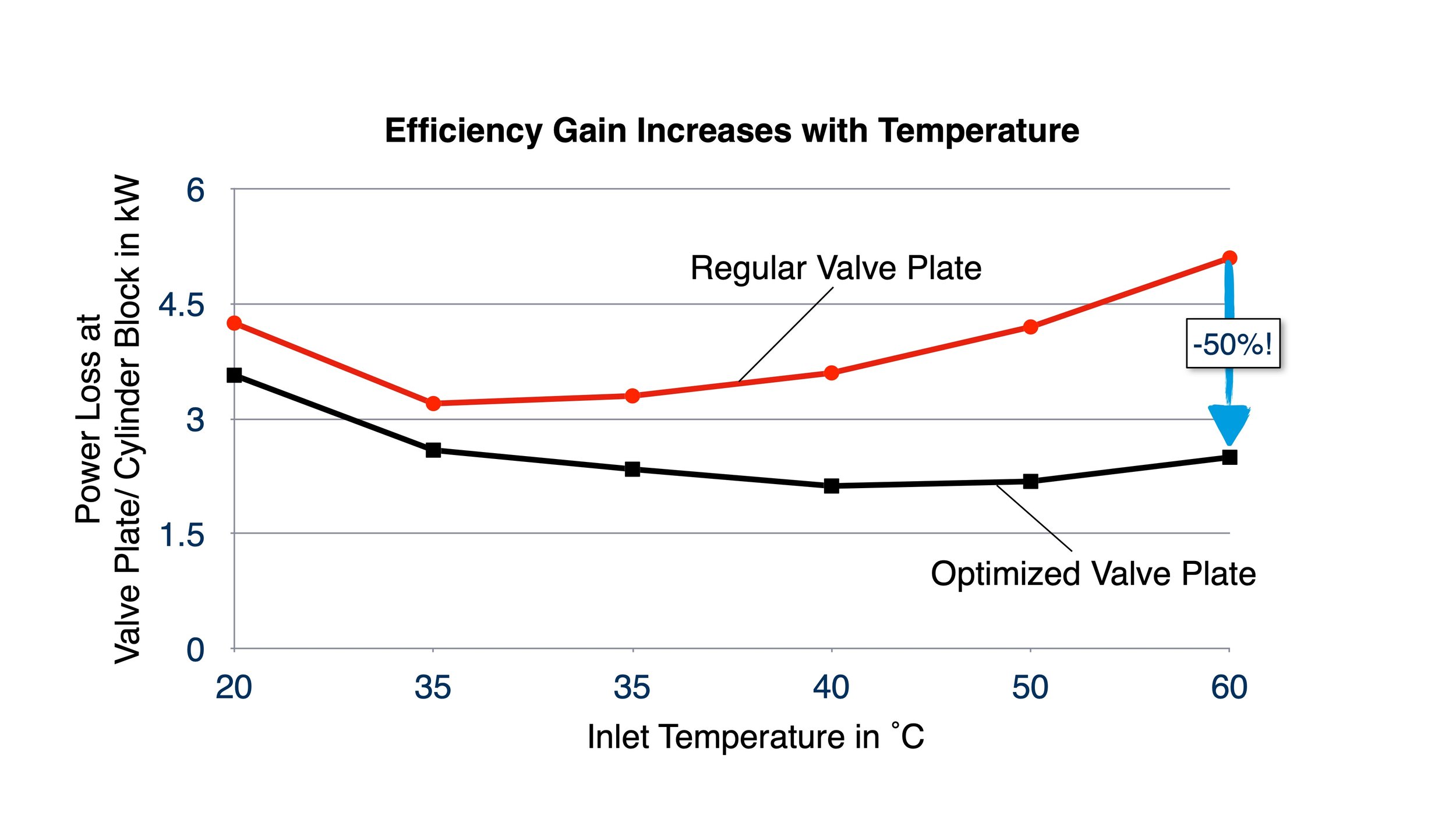

A waved valve plate can slash power losses by over 10% /5-6/.

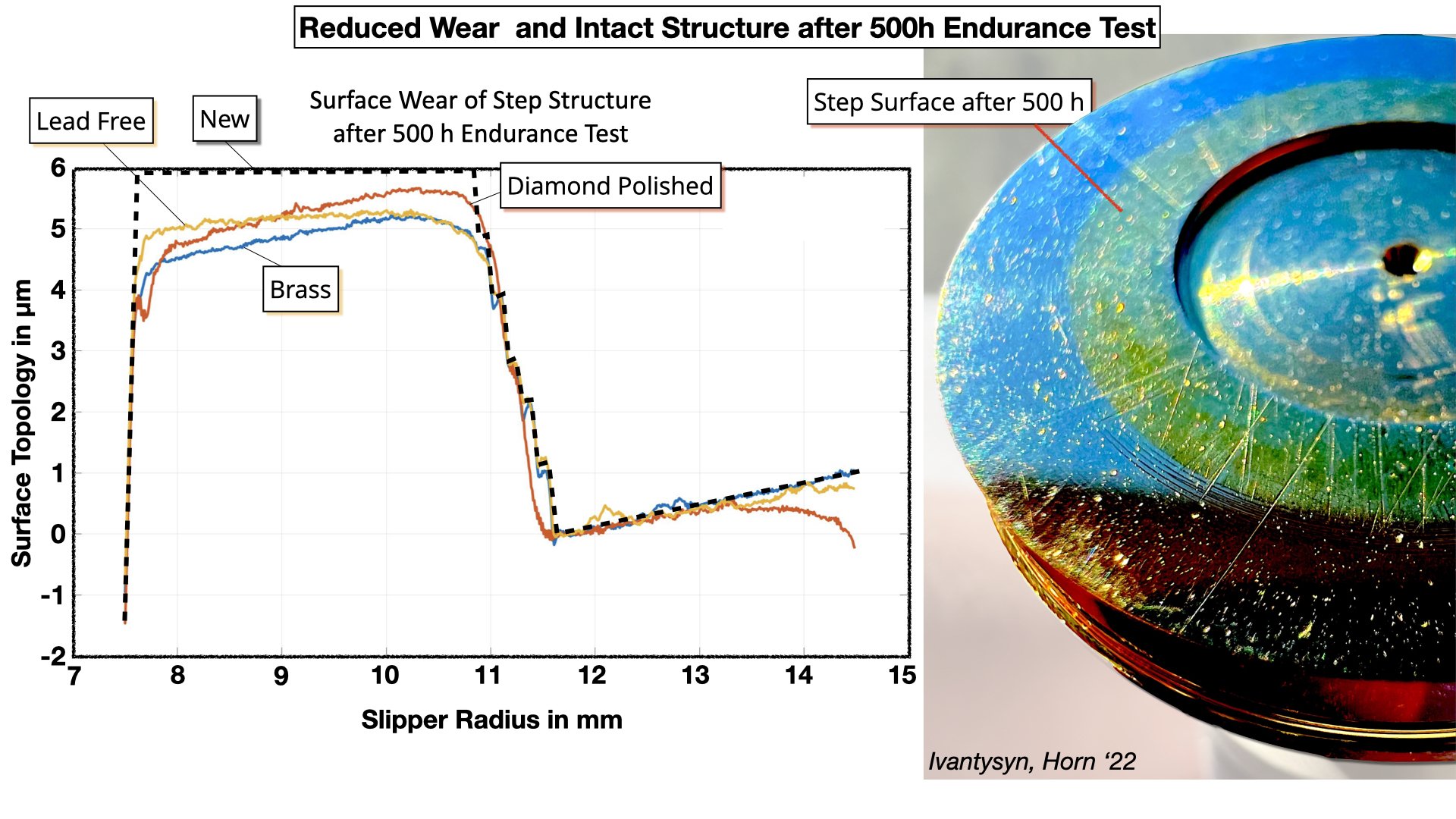

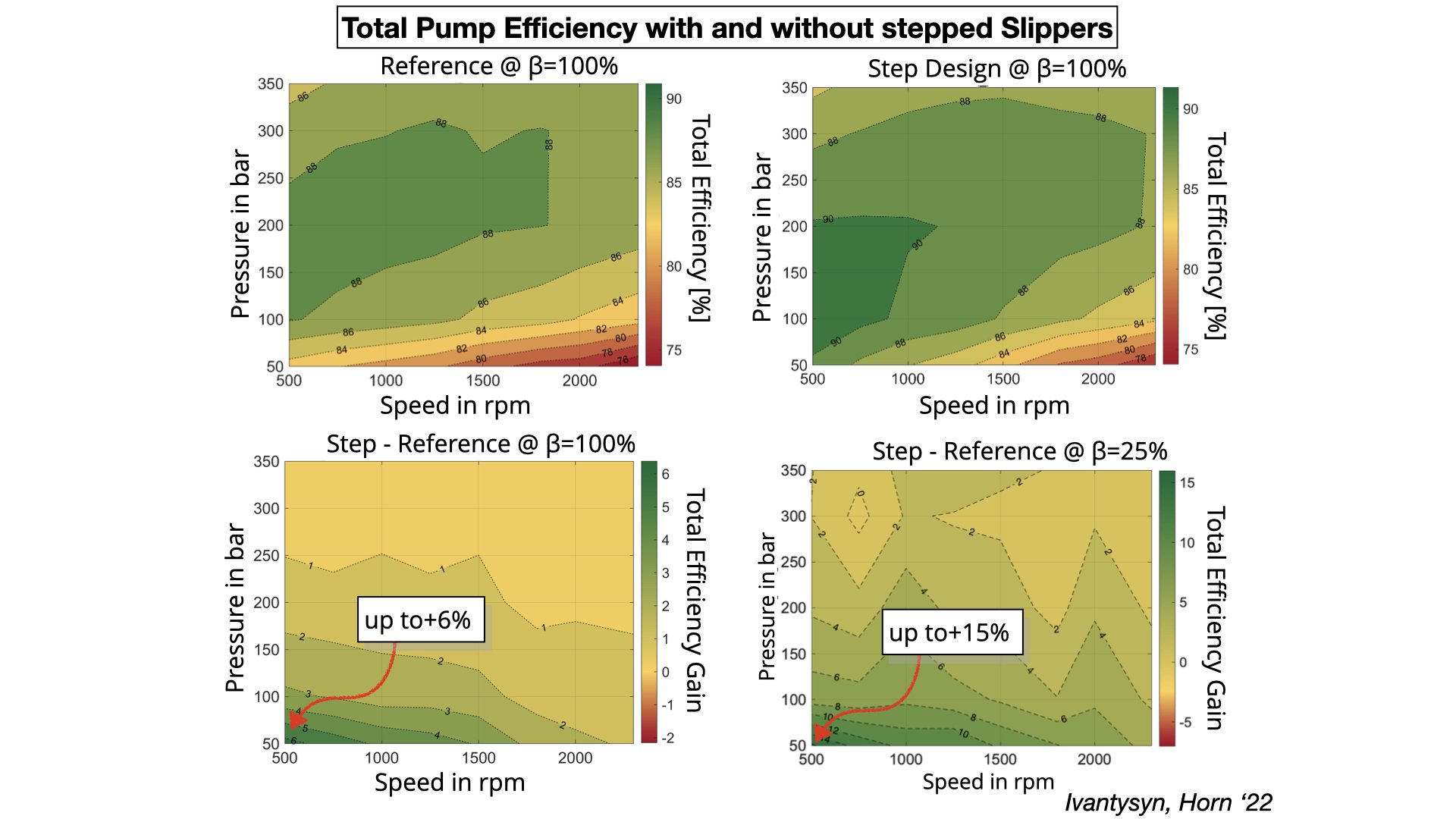

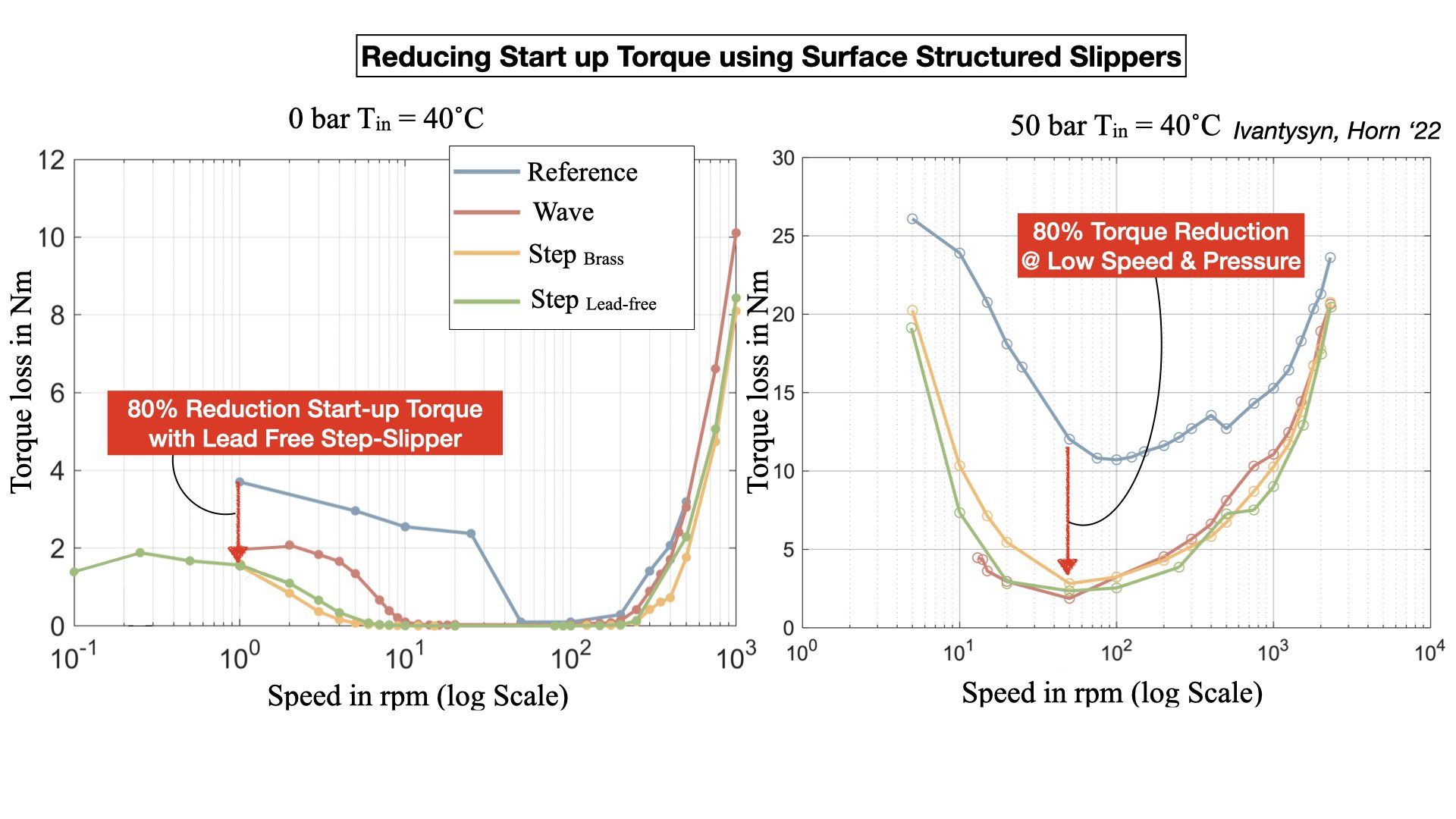

A stepped slipper can reduce startup torque by a staggering 80% while simultaneously boosting efficiency at low-power conditions by more than 20% /1-3/

A uniquely shaped piston, tested in our prototype, cut piston losses by an impressive 20% /4/.

SHS offers you the opportunity to evaluate if your pump is a candidate for these game-changing surface shapes and, crucially, to design the perfect shape for your specific application. This is especially advantageous in the realm of electrification, where frequent startups and low-speed operations are the norm and can greatly benefit from these innovative surface configurations.

And here's the kicker: With the right implementation, the cost of production can be comparable to regular parts, as it eliminates the time-consuming lapping process.

At SHS, we're not just shaping surfaces; we're reshaping the future of hydraulic systems. Join us in revolutionizing efficiency, performance, and cost-effectiveness in your hydraulic applications.

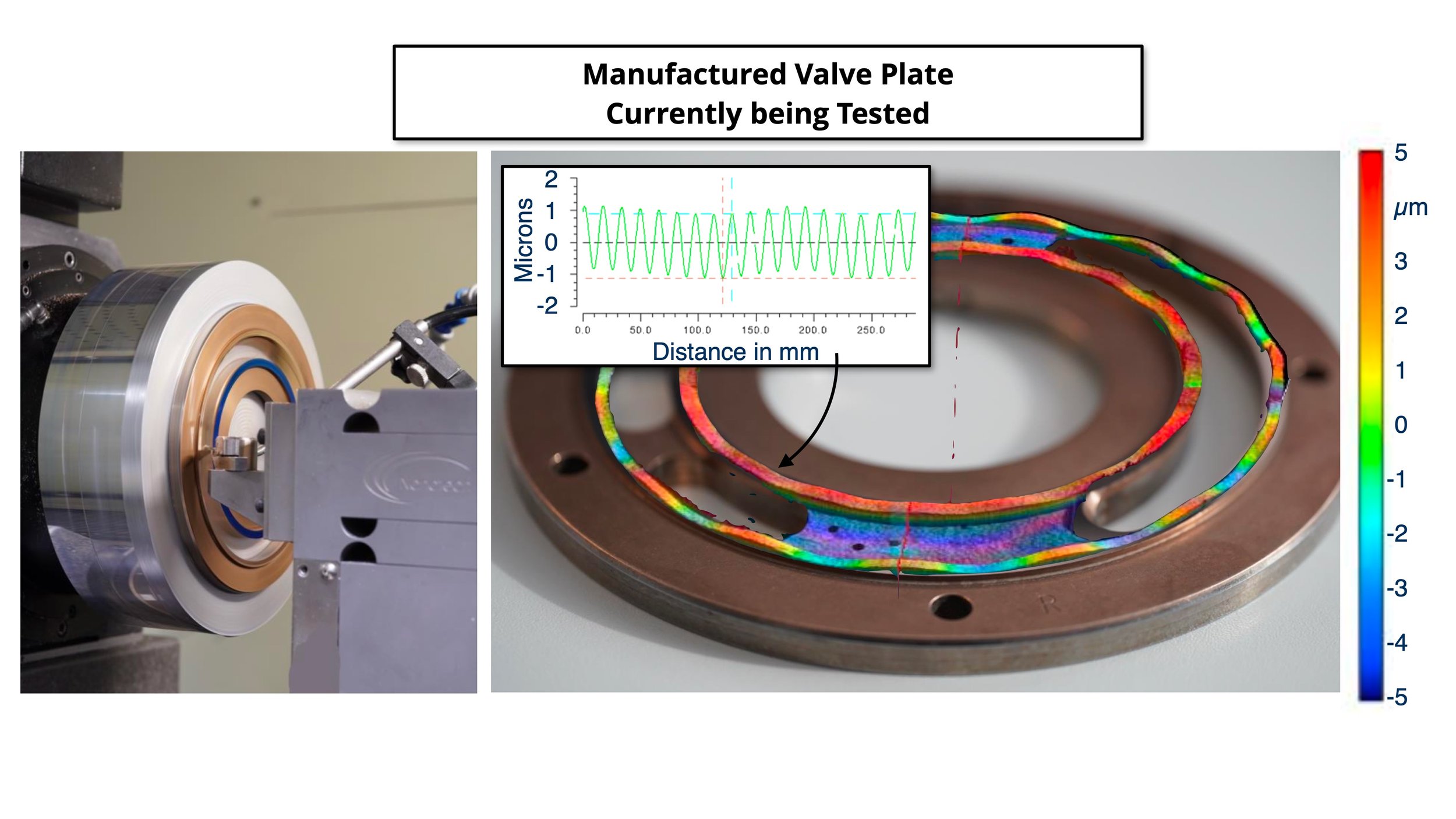

Tested wave structured valve plate

Nearly no wear even of the surface even with lead free brass material

Total pump efficiency Improvement using slippers with step surface structure

Tremendous low speed improvements of the entire axial piston pump by using surface structured slippers

Improvements across all operating conditions

Waved VP is currently being tested

Optimized VP is thermally stable and improves with temperature